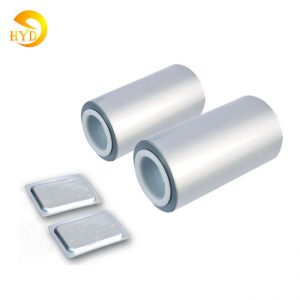

Cold forming blister foil

COLD FORMING BLISTER FOIL is one product dedicated to pharmaceutical industry manufactured by sandwiching aluminum foil between nylon (OPA) and PVC films using dry bond lamination technology. As blisters are formed in this Nylon / Foil / PVC film laminate by pressing laminate into a mould by a stamp without applying heat, the material is called cold forming blister laminate. The laminate offers a near complete barrier for water and oxygen thereby allowing an extended product expiry date due to higher thickness of the foil present in the laminate. The PVC film in alu-alu laminate is commonly used as the contact layer and seal to layer on pharmaceutical blister (as neutral layer for the goods to be filled). PVC is very stiff and does not tend to shrink or spring during cold forming. Once the cold forming process is complete, the PVC helps the cavity hold its shape. In short it ensures the geometric stability after cold forming. The nylon (OPA) film is mainly responsible for the multi-axial forming. Laminating the aluminum with the OPA film doubles the formability of the foil.

- Description

- Inquiry

Structure: NY (OPA) / Al / PVC

Specification:

| WIDTH | THICKNESS ( MICRON) | CORE SIZE | ROLL OD | PRINTING | ||

| NY(OPA) | AL(AA8021) | PVC | ||||

| ≤900mm | 25 | 46-60 | 60 | 76mm | 220m-400m | AVAILABLE |

| Usage ratio of material/layer(Cold Stamping Aluminum:PTP): 4:1&4.7:1 | ||||||

Physical property:

Total barrier performance, conformable, dead fold, light-blind, full sterile condition,perfect commercial finish, good elongation, easy heat seal with PTP Alu-foil to make Alu-Alu packing.

Quantity of penetrated steam: ≤0.5g/(m2.24h)

Quantity of penetrated oxygen: ≤0.5cm3/(m2.24h.0.1Mpa)

Tear strength: OPA/AL≥10.5N/15MM & AL/PVC≥10.2N/15MM

Sealing strength: ≥11.0N/15MM

Application: used for capsule, pills, powders ….

Recommendations as to store conditions:

Max.12 Months at Temperature 15-35℃ and Relative Humidity: 30-65%.