-

Read MoreQuick View

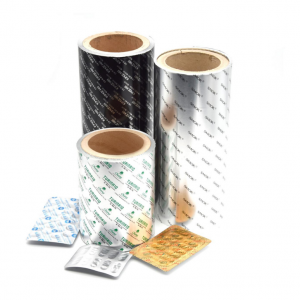

Read MoreQuick ViewBlister pack aluminum lidding foil

The Pharmaceutical Blister Pack Lidding Foil is used as a lid foil in blister packs for hygienic packaging of pharmaceutical preparations such as tablets, pills, capsules and medical devices. This method of packaging ensures that pharmaceutical products meet the required shelf life standard and provide sufficient protection from external influences. Blister lidding foil is sealable to different blister pack substrates such as PVC, PVdC, PET, PP and COLD FORMING Laminate.

-

Read MoreQuick View

Read MoreQuick ViewPTP Alu Foil For Medicinal

The Pharmaceutical Blister Pack Lidding Foil is used as a lid foil in blister packs for hygienic packaging of pharmaceutical preparations such as tablets, pills, capsules and medical devices. This method of packaging ensures that pharmaceutical products meet the required shelf life standard and provide sufficient protection from external influences. Blister lidding foil is sealable to different blister pack substrates such as PVC, PVdC, PET, PP and COLD FORMING Laminate.

Contact us

WhatsApp:+8615071262503

Email:sales806@perfecthengyu.com

-

Read MoreQuick View

Read MoreQuick ViewChild resistant blister pack lidding foil

A Child resistant Blister Pack Lidding Foil is a package which is difficult for young children to open or gaining access to the contents but is not for adults to use properly. The child resistant blister pack has two components namely a base material and lid material. The base material is usually made up of PVC, PET, PP or Cold forming blister laminate whereas the lid material is a laminate having aluminium foil as one of the substrates. The child resistant blister lid foil should provide safety, security and convenience in preventing children from gaining access to the medications.

-

Read MoreQuick View

Read MoreQuick ViewCold forming blister foil

COLD FORMING BLISTER FOIL is one product dedicated to pharmaceutical industry manufactured by sandwiching aluminum foil between nylon (OPA) and PVC films using dry bond lamination technology. As blisters are formed in this Nylon / Foil / PVC film laminate by pressing laminate into a mould by a stamp without applying heat, the material is called cold forming blister laminate. The laminate offers a near complete barrier for water and oxygen thereby allowing an extended product expiry date due to higher thickness of the foil present in the laminate. The PVC film in alu-alu laminate is commonly used as the contact layer and seal to layer on pharmaceutical blister (as neutral layer for the goods to be filled). PVC is very stiff and does not tend to shrink or spring during cold forming. Once the cold forming process is complete, the PVC helps the cavity hold its shape. In short it ensures the geometric stability after cold forming. The nylon (OPA) film is mainly responsible for the multi-axial forming. Laminating the aluminum with the OPA film doubles the formability of the foil.

-

Read MoreQuick View

Read MoreQuick ViewTropical blister aluminum foil

Tropical Blister Aluminum Foil Used for tablets or capsules and other solid pharmaceutical packaging.

- Structure:OPA + AL + VC

- Specification:

- Width: ≤1000mm,

- Total Thickness:0.09-0.10mm,

- Core size: 76mm.

- Properties: Total barrier performance, light-blind, deadfold, full sterile condition, perfect commercial finish, easy laminate with PVC film.

-

Read MoreQuick View

Read MoreQuick ViewPharmaceutical strip foil

The Pharmaceutical Strip Foil is used to pack pharmaceutical products like tablets, pills, capsules, effervescent tablets and powders which are sensitive to moisture, oxygen and light. The laminate is also used to pack medical devices. Strip packs are a convenient packaging solution that allows patients to carry dosages as per the prescription without compromising with safety of the product and its recognition.

-

Read MoreQuick View

Read MoreQuick ViewEmbossed aluminum foil cover lid

The Lidding Foil is used as a lid on plastic cups and containers which not only provides perfect closure to the cup but makes it pilfer proof and provides protection from external influences. The low permeation properties of the foil to water vapor and oxygen ensures the required shelf life. The heat seal lacquer used in lidding foil can be made sealable to different cup/jar substrates such as PET, PP, PS, HDPE and PVC. Lidding foil with a universal coating which can seal with multiple substrates is also available.

-

Read MoreQuick View

Read MoreQuick ViewAluminum foil cover lid

The Lidding Foil is used as a lid on plastic cups and containers which not only provides perfect closure to the cup but makes it pilfer proof and provides protection from external influences. The low permeation properties of the foil to water vapor and oxygen ensures the required shelf life. The heat seal lacquer used in lidding foil can be made sealable to different cup/jar substrates such as PET, PP, PS, HDPE and PVC. Lidding foil with a universal coating which can seal with multiple substrates is also available.

-

Read MoreQuick View

Read MoreQuick ViewLaminated aluminum foil roll

Used for pharmaceutical and food packing, like bags and sachets.

Structure:PET + Alu+ PE or CPP

Physical property

1) One side of AL laminated with PET

2) Another side laminated with the PE or CPP film

3) Flat,even and clean. No perforation\peculiar odor impurity\ conglutination, No obvious abnormal (separation, damage,air bubble,wrinkle,dirt) between the layers. -

Read MoreQuick View

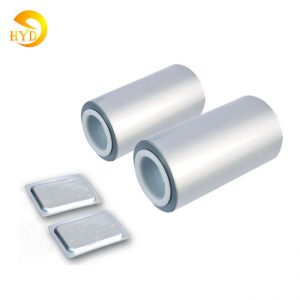

Read MoreQuick ViewTwo piece induction aluminum sealing foil liner

Sealing Liner for plastic and glass bottle. Two piece seal liner and one piece aluminum foil and die cut pieces aluminum foil are widely used in the new packaging, not only improve the upgrade of products, prevent moisture, extend the shelf life, also to strengthen the security performance, it`s the first choice in packaging industry.

-

Read MoreQuick View

Read MoreQuick ViewOne piece induction aluminum sealing foil liner

Sealing Liner for plastic and glass bottle. Two piece seal liner and one piece aluminum foil and die cut pieces aluminum foil are widely used in the new packaging, not only improve the upgrade of products, prevent moisture, extend the shelf life, also to strengthen the security performance, it`s the first choice in packaging industry.

-

Read MoreQuick View

Read MoreQuick ViewAluminum foil for refrigerator heating element

Structure:

heat seal lacquer + aluminum foil

heat seal lacquer + aluminum foil + adhesive + release paper liner or PET liner

Application: for refrigerator heating element, to stick the PVC wire.

- Home

- Products

Products

Copyright © Hubei Perfect Hengyu Packing Material Co., Ltd All Rights Reserved.