Capsule blister packaging? Advantages and disadvantages of Blister aluminum foil in packaging process

Capsule blister packaging? Advantages and disadvantages of Blister aluminum foil in packaging process

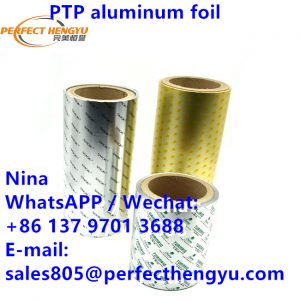

Usually, we mainly take capsules and tablets aluminum foil .

Capsules are usually divided into hard capsules and soft capsules. Hard capsule, also known as hollow capsule, is composed of two parts: cap and body

Capsule: the advantage is that the disintegration time in the intestine after oral administration is faster than that of tablets, generally 5-10 minutes. It has less irritation to the intestines and stomach and is not easy to damage the gastric mucosa. It should be taken before meals. Moreover, the capsule covers the smell of the drug itself. It is the only type of drug that does not have to endure the smell of the drug.

The disadvantages are that the capsule drug particles are relatively large, the production process is simple, there are many impurities, relatively many side effects, the capsule shell does not contain effective components, and the capsule shell is easy to be softened by water, which is not conducive to storage in wet weather.

Hard capsules were invented 1500 years ago and are now widely used.

At present, the capsule is packed by blister packaging machine. High speed blister packaging can be cut more than 60-100 times in one minute. Now it is not difficult to pack more than 100000 capsules per day.

But it is difficult to ensure that tens of millions of products in the packaging process is not a problem.

What are the problems?

The defects of capsule blister plate are divided into three categories:

Class a serious defects (cavitation, half grain, crack, no batch number, batch number perforation, etc.)

Class B General defects (batch number too close to blister, hair, aluminum foil fold, aluminum foil deviation, etc.)

Class C minor defects (foreign matters of the same color, unclear reticulation, blistering, etc.)

Vacuole: it mainly refers to that the capsule can’t fill the eye of the bubble, and the medicine you buy is less than a few particles, resulting in a variety of original drugs. Such as static electricity, debugging, environment, poor drug application, unstable operation, jump out, etc! impossible to guard against!

So when we buy the above drugs and don’t take them in a hurry, we may have a risk.

Pharmaceutical enterprises will certainly solve the above problems in the production process. The main thing is to strengthen the management and inspection.

More pharmaceutical enterprises add high-cost testing equipment in the back. The testing equipment is divided into on-line and on-line

Online is to test while packaging, but the detection range and accuracy are limited

In line detection is to add detection equipment in the back. Conduct full inspection of products. Minimize the flow of defective products to the market.

Don’t look at a small capsule version. It may be very popular in the production process before production. Package appearance, capacity, moisture, microorganism, tightness, text, etc

Sales Manager :Nina

WhatsApp:+86137 9701 3688

Email: sales805@perfecthengyu.com